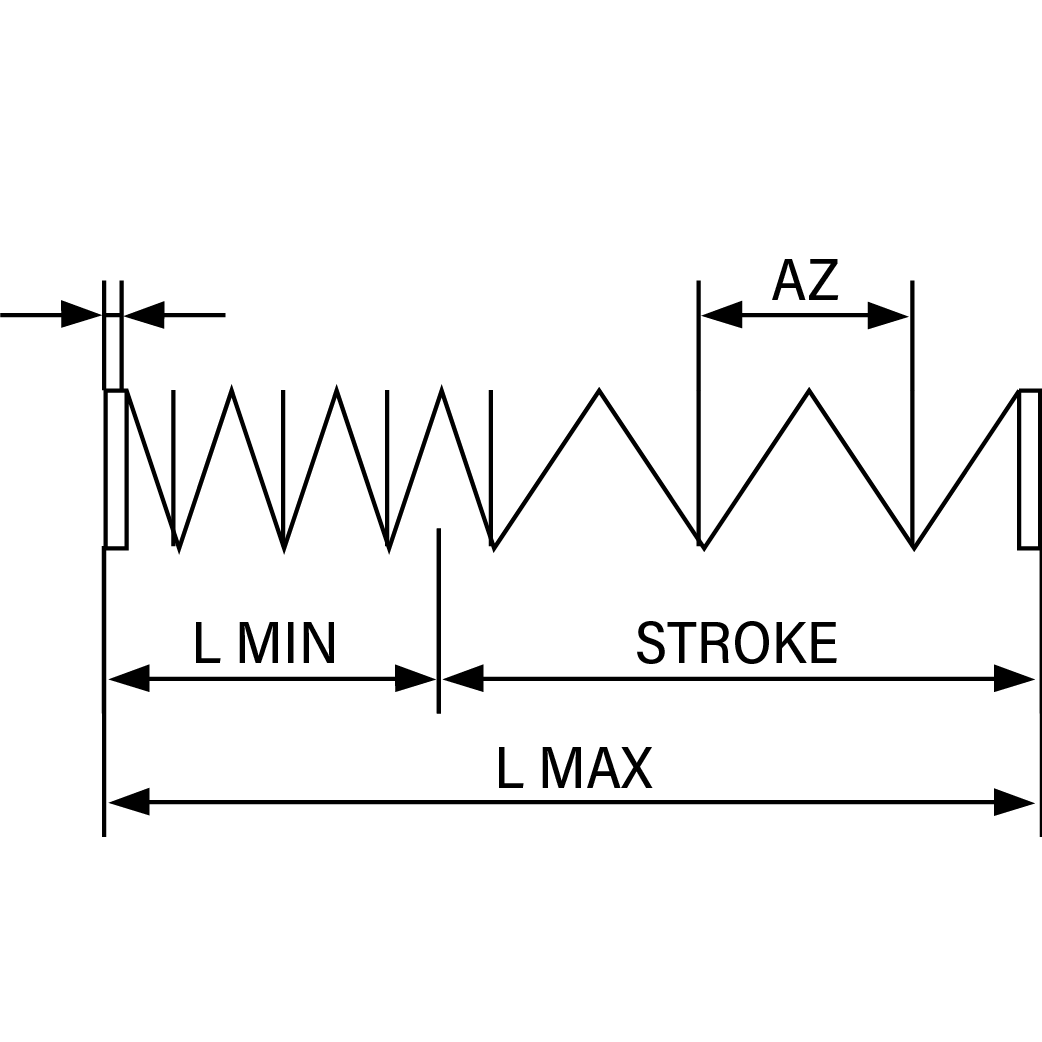

| Fold Height (E) | Extension Per Fold (AZ) |

|---|---|

| 15 | 14 |

| 17 | 18 |

| 20 | 24 |

| 24 | 32 |

| 30 | 44 |

| 35 | 54 |

| 40 | 64 |

| 45 | 74 |

COATED FABRIC BELLOWS AND WAY COVERS

Industrial coated fabric bellows are great for dust protection, laser machines, and guideways that don't see high chip loads. They offer maximum compression and flexibility in a wide range of materials for a wide range of environments. Our bellows can be made folded to cover multiple sides, flat to cover a single side, or round for protecting shafts and other cylindrical machine components.

TECHNICAL DATA

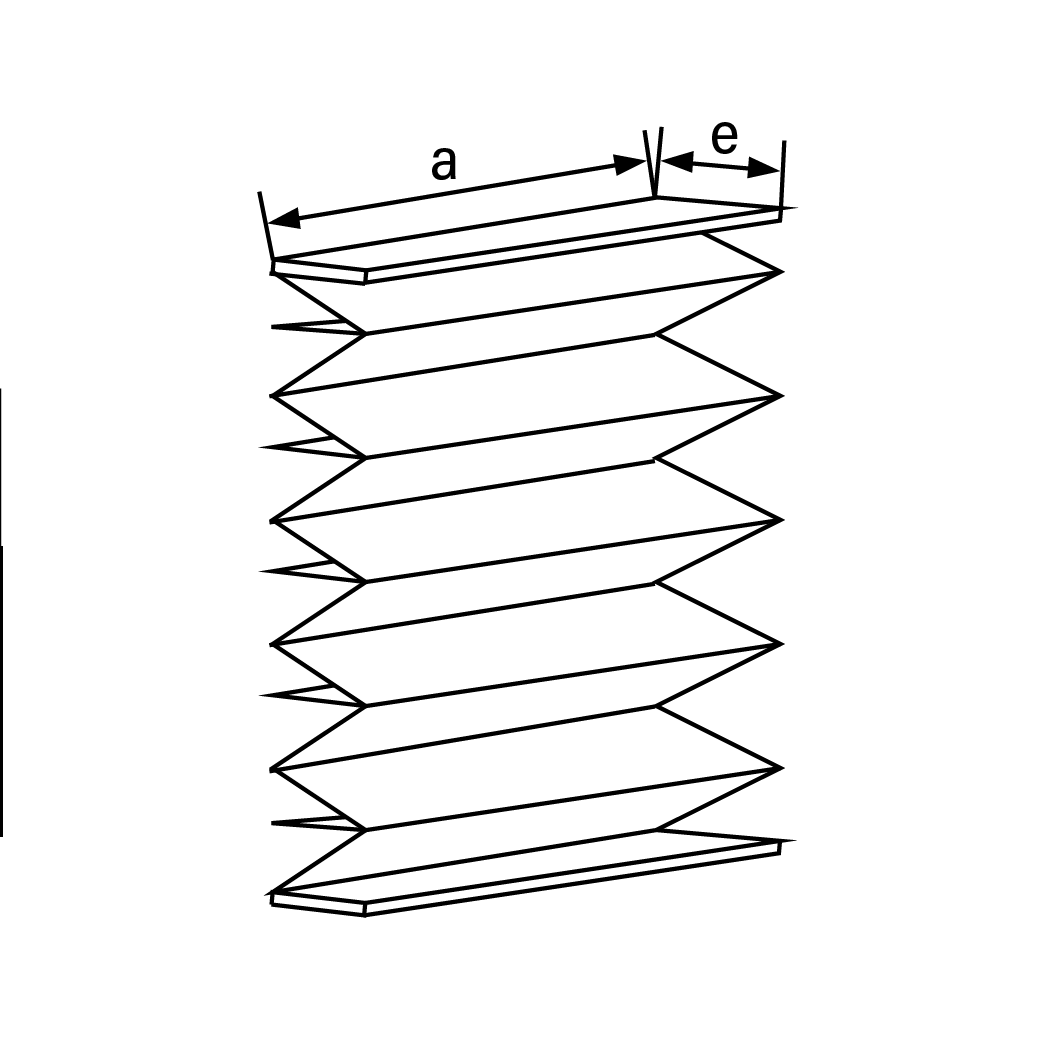

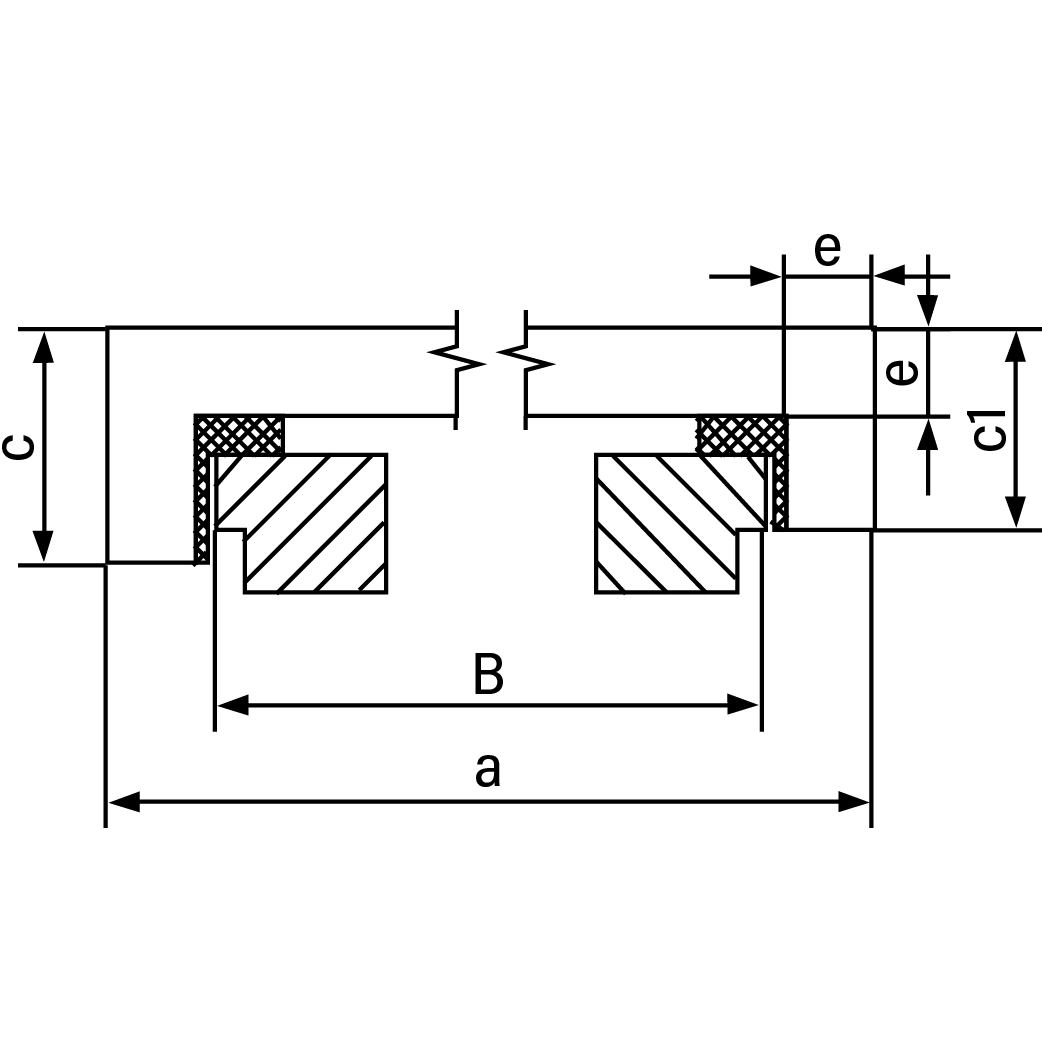

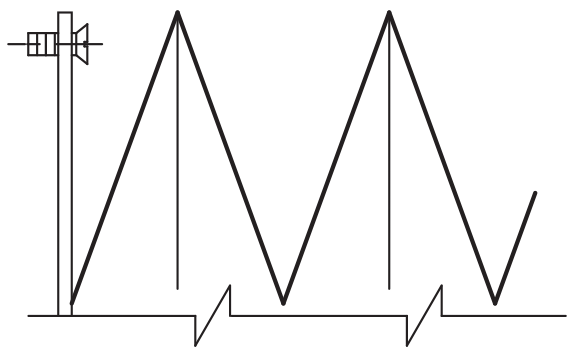

FLAT BELLOW

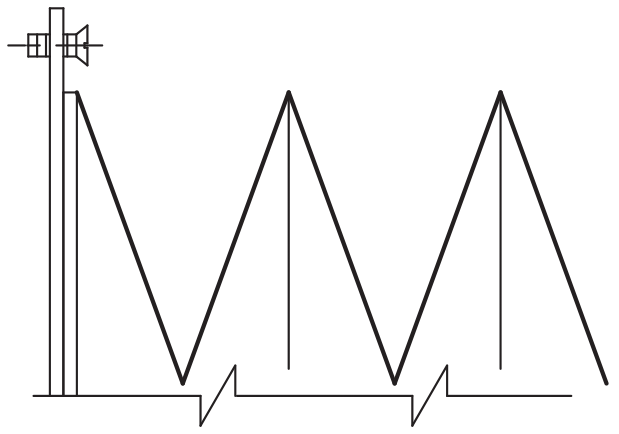

FOLDED BELLOW

Fold Height (E) Extension Per Fold (AZ) 15 18 17 22 20 28 24 36 30 48 35 58 40 68 45 78

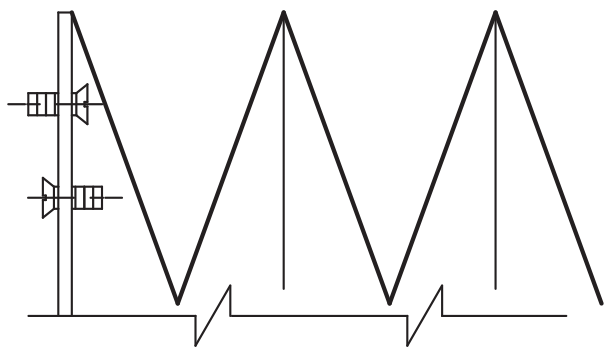

standard mounting options

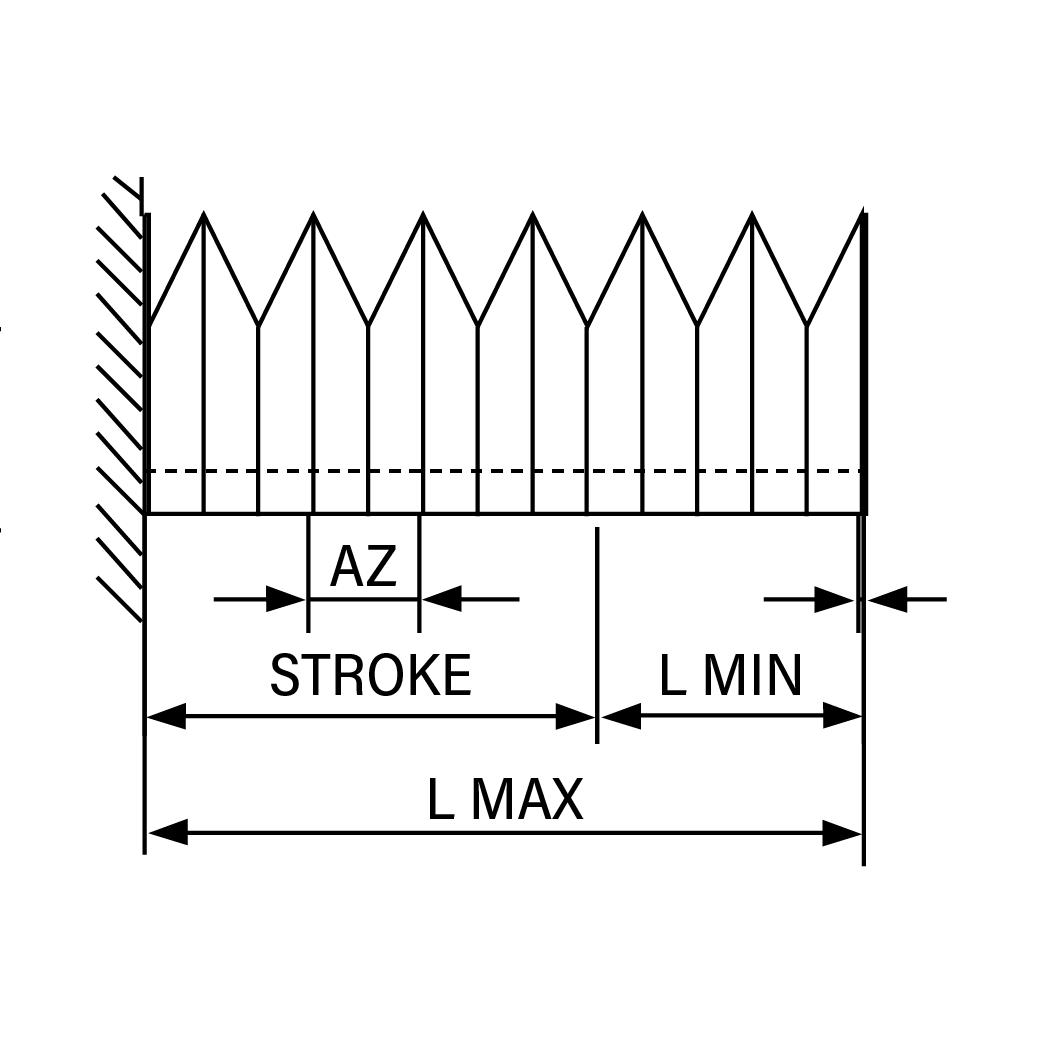

HALF FOLD

Limits extension of the first fold for outside mounting.

EXTERNAL FLANGE

Allows for full extension of the first bellow for outside mounting above the bellows.

FULL FOLD

Allows for full extension of the first fold for inside mounting.

VELCRO

Supplied with adhesive backed velcro fastener for simple and quick inspection of machine components (dry applications).

HENNIG HELPS RESOURCE HUB

A destination for manufacturers who simply don't have time for downtime—we're here to help make you successful.

MATERIAL OPTIONS FOR COATED FABRIC BELLOWS

Our bellows are made exclusively from high-quality plastic fabrics and foils. We select the cover material and processing according to the design ambient conditions. Decisive factors are the mechanical and thermal strain of the bellows as well as the type of swarf and aggressiveness of the agents used. Exact details of the used materials may be gathered from the table of materials above.

Specification Number Coating Ext Int Carrier Thickness (mm) Color Heat Sealed Stitched Lamella Round Stitched Wear Resistance Oil Grease Coolant Resistance Surface Stability Swarf Weld Splatter Forging Scale Resistance Self Extinguishing Flame Resistance Extension Compressions Ratio OZ-PUR PUR/PUR Polyester 0.35 Black x x x + + ++ + o - + GN807 PUR/PUR Polyester 1.00 Black x x x + + - - o - - NA-784 TPU/TPU Polyester 1.00 White x x x x + + - - o - - OZ-PUR PUR/PUR Polyester 0.22 Black/Grey x x + + o o o - ++ OZ-23 PVC/PVC Polyester 0.23 Black x x + + o - - - ++ OZ-35 PVC/PVC Polyester 0.36 Black x x x + + + o o - + ALUM-ARAMID ALU/ALU Nomex 0.35 Black x x x + + + ++ ++ + + PURT/TEFLON PTFE/PUR Polyester 0.30 Black x x x ++ ++ ++ o o - + NEOPRENE NEP/NEP Nylon 0.40 Black x x x x ++ ++ ++ ++ o - o HYPALON HYP/HYP Nylon 0.40 Black x x x x + + + o o - o

++ Excellent + Good o Suited Under Certain Conditions - Unsuitable

TABLE OF MATERIALS

Commonly Used Materials Details Polyurethane (PUR) Temperature Resistance up to 120° C Aluminized Aluminum-coated Nomex® - temperature resistance up to 400ºC (only for stitched version) Nomex® Flame-resistant material, suitable for laser applications Kevlar® High strength, abrasion resistant, puncture resistant Polyvinylchloride (PVC) Material does not continue burning if ignited (self-extinguishing) Teflon® Polytetraflourethylen (PTFE) Anti-adhesive, high-chemical and thermal resilience, dirt and water-repelling, corrosion-proof