Mobile Chip Conveyors

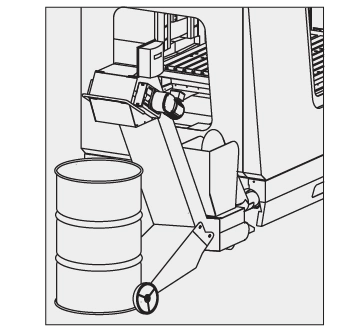

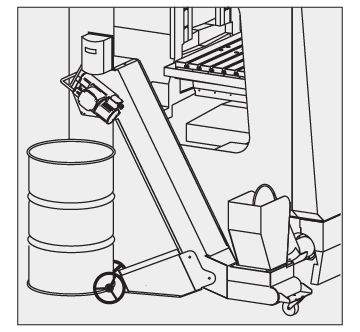

The mobile conveyor provides machine operators with an efficient and convenient way to lift chips into full size barrel or hopper-high receptacles when using auger-style chip conveyors with chip flumes. It reduces machine clean-out effort and eliminates back related fatigue. The portable conveyor can be used for periodic clean-out of multiple machines or dedicated full time to any machine generating high volumes of chips. Position the conveyor under the chip chute of any auger chip flume, set your chute orientation, plug it in, and turn it on. Coolant that collects in the conveyor will be carried out by the chips so the conveyor never requires draining.

FEATURES

- Overload/jam protection

- Variable Speed Drive | 0.8 m/min - 3.3 m/min (standard)

- Paint | Textured gray, black (standard); Custom colors required

- Incline Angle | 60º (standard)

- Low Profile Design

Limitations for the mobile chip conveyor include:

- Cannot be used on machines without an internal auger as the primary chip removal system

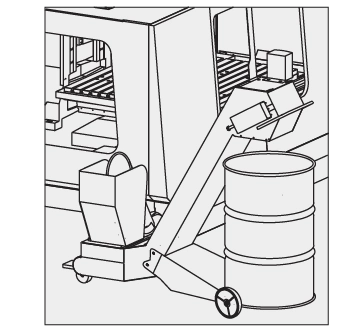

Adjustable Chip Chute Option

The opening of the chip hopper may be oriented directly toward the tail section of the conveyor, to the right, or to the left, by unscrewing the four bolts holding the hopper in place, removing it, rotating it to the desired position, and bolting it back in place.

A. Toward Tail Section

B. With APCQ

C. To Left

D. To Right

HENNIG HELPS RESOURCE HUB

A destination for manufacturers who simply don't have time for downtime—we're here to help make you successful.

frequently asked questions

Chip conveyors are required in machining production to remove chips from the work area of a CNC machine and can be processed for recycling.

Chip conveyors are used to remove chips from machine tools and put them into a collection container while also separating the chips from the coolant. Chips are removed from the machine, so it does not become jammed with chips over time.

Depending on the material and the type of chip produced, there are different types of chip conveyors with different technology: hinge belt conveyors, scraper belt conveyors, magnetic conveyors, medium filtration conveyors (PureFlow), high-end filtration (CDF, or chip-disc filtration), and auger conveyors to name a few. To view all of Hennig’s conveyor types, visit https://hennigworldwide.com/conveyors-and-filtration/.

Chip conveyors present a number of advantages for companies, including in increase in labor productivity, minimizing risk of accidents, and recycling of clean coolant after filtration.