| Fold Height (E) | Extensions Per Fold Flat (AZ) | Extensions Per Fold Folded Az | Width of Lamellas (K) |

|---|---|---|---|

| 24 | 27 | 33 | 61 |

| 30 | 39 | 45 | 76 |

| 35 | 49 | 55 | 81 |

| 40 | 59 | 65 | 91 |

| 45 | 69 | 75 | 101 |

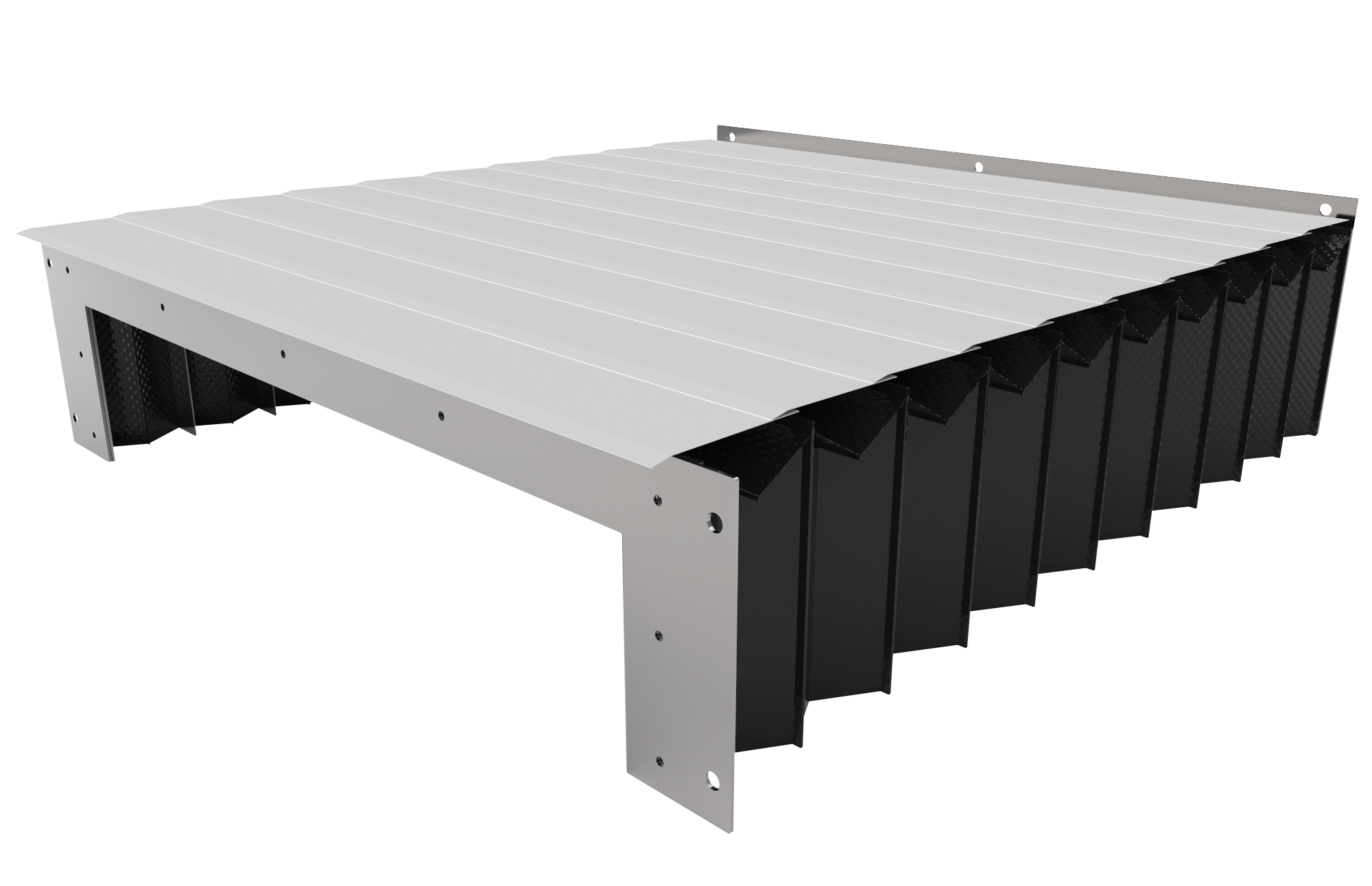

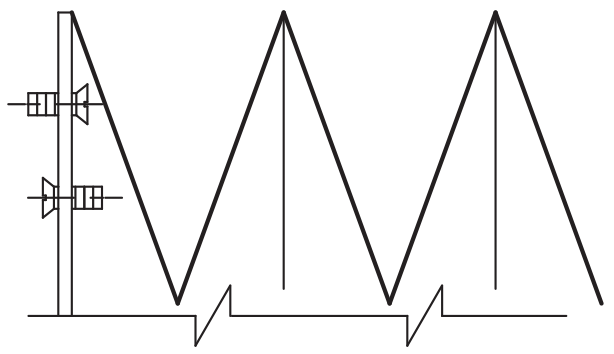

Fixed Steel Lamella Bellows

Have a particularly tough requirement? The fixed steel lamella bellow type fills the gap between telescopic steel covers and conventional bellows. The lamella bellows are based on our heat sealed or stitched designs. Each fold has its own guide frame, which is secured to the cover material. Lamellas made from stainless steel protect the bellows against red-hot and sharp-edged swarf as well as mechanical strain, while offering the compression and flexibility of traditional bellows.

Available in fixed or movable versions.

TECHNICAL DATA

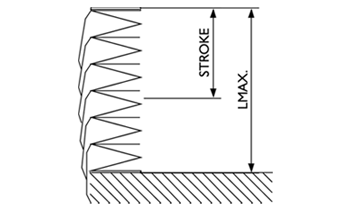

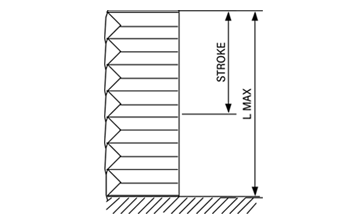

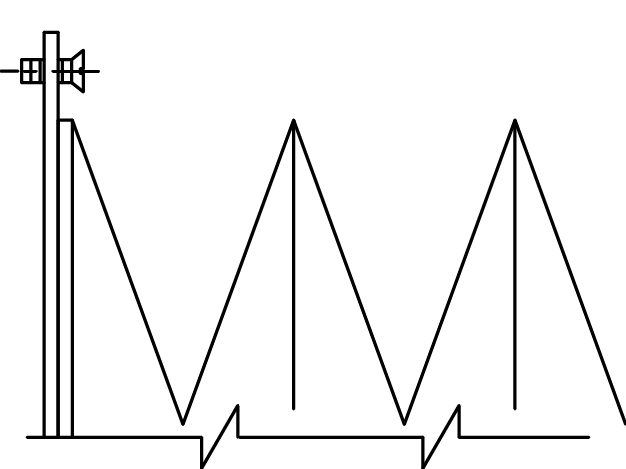

FLAT BELLOW

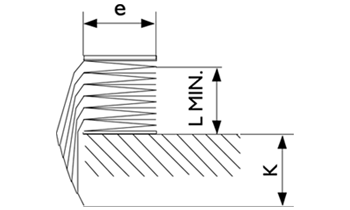

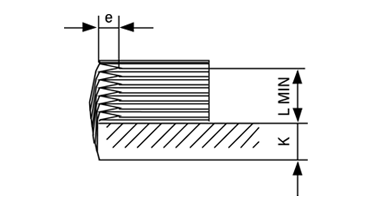

FOLDED BELLOW

Fold Height (E) Extensions Per Fold Flat (AZ) Extensions Per Fold Folded Az Width of Lamellas (K) 24 27 33 61 30 39 45 76 35 49 55 81 40 59 65 91 45 69 75 101

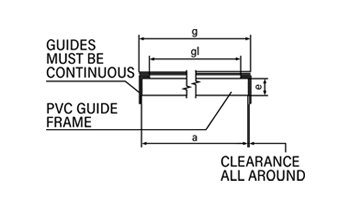

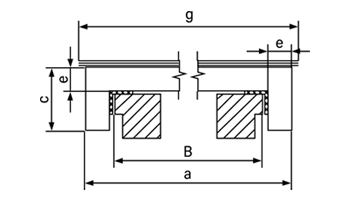

standard mounting options

FULL FOLD

Allows for full extension of first fold for inside mounting.

EXTERNAL FLANGE

Allows for full extension of first fold with outside mounting above bellows.

HENNIG HELPS RESOURCE HUB

A destination for manufacturers who simply don't have time for downtime—we're here to help make you successful.

MATERIAL OPTIONS FOR FIXED STEEL LAMELLA BELLOWS

Our bellows are made exclusively from high-quality plastic fabrics and foils. We select the cover material and processing according to the design ambient conditions. Decisive factors are the mechanical and thermal strain of the bellows as well as the type of swarf and aggressiveness of the agents used. Exact details of the used materials may be gathered from the table of materials above.

Carrier Coating Ext Int Specification Number Thickness (mm) Heat Sealed Stitched Steel Clad Round Stitched Wear Resistance Oil Grease Collant Resistance Swarf Weld Splatter Forging Scale Resistance Flame Resistance Self Extinguishing Surface Stability Extension Compressions Ratio Polyester PUR / PUR OZ-PUR 0.35 x x x + + + - o ++ + Polyester PUR / PUR ERA 7810 0.22 x x + o o - o o ++ Kevlar PUR / PUR PUR-KEVLAR 0.36 x x x x ++ + + + + ++ + Polyester PVC / PVC OZ-23 0.23 x x + - - - - o ++ Polyester PVC / PVC OZ-35 0.36 x x x + + o - o + + Nomex ALU / - ALUM-ARAMID 0.35 x x x + o ++ + ++ + + Polyester PTFE / PUR PUR / TEFLON 0.3 x x x ++ ++ o - o ++ + Nylon NEP / NEP NEOPRENE 0.4 x x x x ++ ++ ++ - o ++ o Nylon HYP / HYP HYPALON 0.4 x x x x + ++ o - o + o

++ Excellent + Good o Suited Under Certain Conditions - Unsuitable

table of materials

Commonly Used Materials Details Polyurethane (PUR) Temperature Resistance up to 120° C Polyurethane (PUR) Aluminized Temperature Resistance up to 400° C (stitched type only) Nomex Flame Resistance. Ideal for laser machines Kevlar High Strength. Abrasion and puncture resistant. Polyvinylchloride (PVC) Self Extinguishing Teflon Polytetraflourethylen (PTFE) Anti-adhesive. High chemical and thermal resilience. Corrosion proof. Dirt & water repelling.