| Type | Span 500 mm | Span 1000 mm | Span 1500 mm | Span 2000 mm | Weight (kg/m²) |

|---|---|---|---|---|---|

| AGS I | 1950 | 488 | 216 | 122 | 30.4 |

| AGS III | 3250 | 815 | 370 | 168 | 31.1 |

| Stainless Steel | * | * | * | * | * |

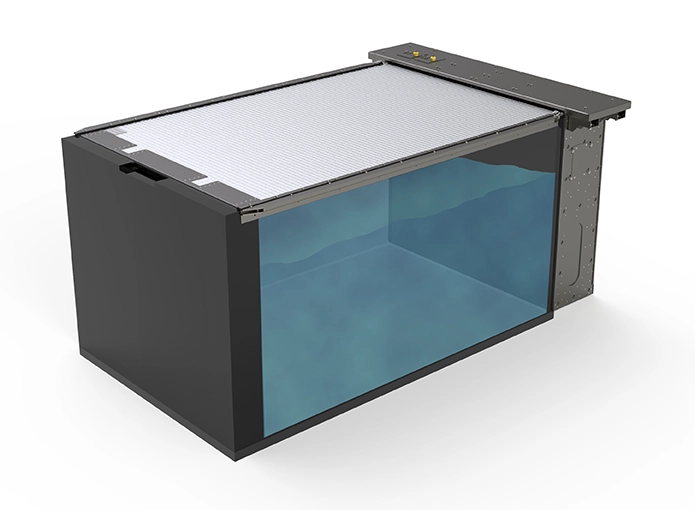

...and bolster facility safety OSHA compliance with stable, low maintenance walk-on covers that move dynamically to allow access to the pit when you need it.

You can find them in most large manufacturing operations: big open chasms and deep pits built to hold heavy machinery or contain hazardous chemicals. The covering and securing of these huge hazards is vital for the safety of employees and the overall facility, but you don’t want to make your equipment hard to reach.

For that reason, Hennig safety pit covers are the perfect solution. Because they are load-bearing and removable, you don’t have to sacrifice safety for accessibility. They’re the best of both worlds.

Regardless of the size of the area being protected, Hennig Safety Pit Covers easily endure constant use and (dependent on material) will support the weight of heavy chip loads and personnel.

For additional features and options, call us to discuss solutions best suited for your applications.

Load capacity in kg per 1000 mm length

Type Span 500 mm Span 1000 mm Span 1500 mm Span 2000 mm Weight (kg/m²) AGS I 1950 488 216 122 30.4 AGS III 3250 815 370 168 31.1 Stainless Steel * * * * *

*to be determined by application

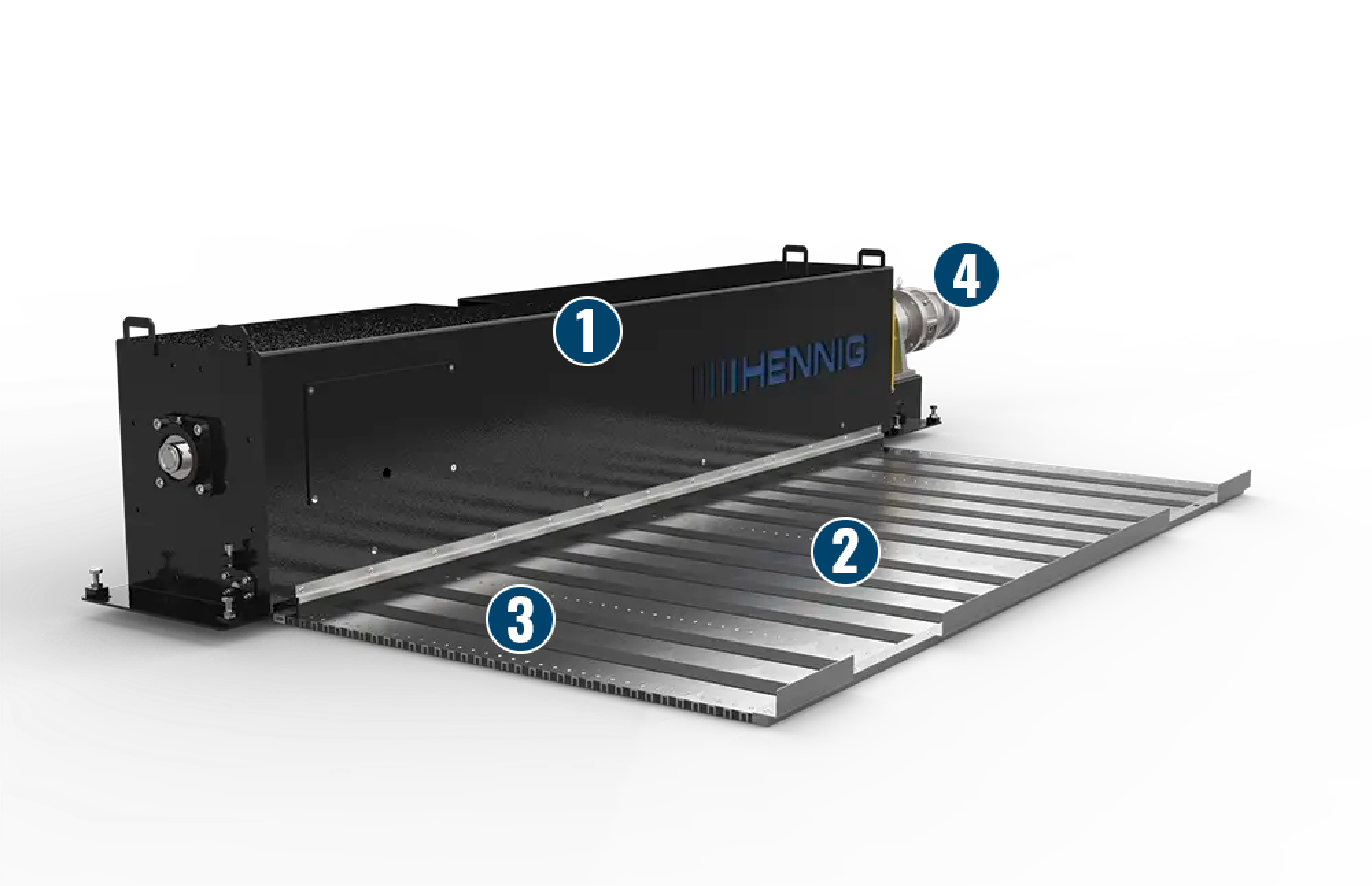

Case size (approx.)

Type Extract 1000 mm Extract 3000 mm Extract 5000 mm Extract 10000 mm Extract 20000 mm AGS I 400 480 540 660 850 AGS II 500 600 680 850 1100 AGS III 450 510 600 740 940 Stainless Steel * * * * *

*to be determined by application

A destination for manufacturers who simply don't have time for downtime—we're here to help make you successful.

Work with our facility safety experts to design and build custom pit covers with the best materials and features for your specific environment to maintain a safe and OSHA-compliant solution for your shop. Listed below are some key choices to think about. Please contact us for your specific request.

Stainless Steel with Aluminum Extrusions

AGS (mini, I, II)

The covering or securing of open pits is necessary for overall facility safety. The measures to protect against falls and falling objects include:

Depending on the requirements of your pit and the work area, the choice of material for your cover will vary. Our safety devices made of aluminum and stainless steel are stable and easy to care for, protect against damage and dirt, and are automated. Please contact us for your specific request.